Customers have high expectations and meeting them is critical. For a new electronic product, the level of detail that goes into the low-level design is less important than the user experience.

For many OEMs, focusing on the user experience is where they can add real differentiation.

Although they are all different at a high level, many electronic systems are similar underneath. Standards such as Bluetooth, Wi-Fi, and Ethernet provide a common interface for connectivity. It is difficult to include any real value-add here, as the function is binary; it either works or it doesn’t.

In order to gain market share, manufacturers need to present the best user experience. With limited engineering resources, teams need to focus on where they add the most value. By working with a partner like Napino Digital Solutions, the effort involved with the design, test, manufacture, and assembly – within restricted cost windows – becomes much more manageable.

Cut BoM costs with the right ODM

Electronic design is a constantly developing discipline. The number of new electronic components that come to the market each year is staggering and each new generation offers improvements on the last. The pace of change is rapid, but the penalty for not keeping up with it can be significant.

What may have needed five integrated circuits a generation ago might now be possible using a single device. This level of integration can reduce the PCB area, system power budget, and total cost of the Bill of Materials. To OEMs, it could represent the difference between profit and loss. Engineers need to know this and make sure they choose the best solution for their application.

The semiconductor manufacturing industry is global, with key players in most continents. New product introductions are frequent, which means it can be difficult for design engineers to keep up with the latest development. This is where an ODM (original design manufacturer) partner like Napino can really help. The expertise of these ODMs is built on navigating rapid and complex design flows, enforced by successfully delivering many products.

Add Napino to your design team

Napino is one of India’s leading electronic ODMs focused on providing advanced design and manufacturing services. It is experienced in developing products in every vertical sector, from Automotive to Medical and the IoT. Napino offers a range of design services that meet international standards and certifications.

A large OEM may have many new products in development at any one time. Engineering resources are under extreme pressure to hit their milestones. However, design isn’t always simple, and estimating the effort required to develop that low-level driver or integrate that touch-sensitive display can be a challenge.

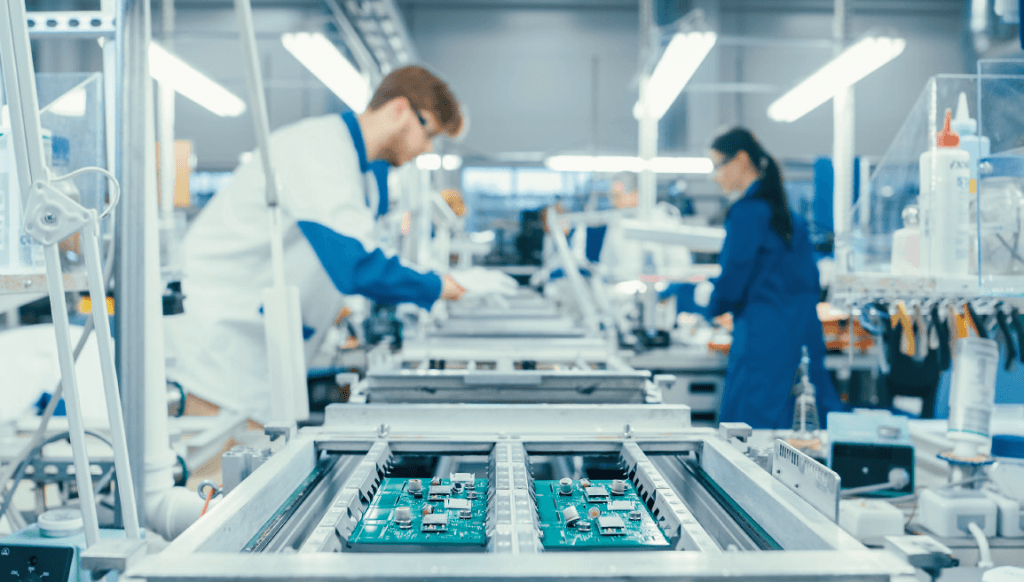

Outsourcing all or part of a product design can relieve that pressure. Napino has a team of over 150 experienced R&D engineers, located in two design centers, who are ready to provide the expertise and extra capacity OEMs need. Napino’s design resources are extensive, covering both hardware and software design. Its engineering teams are experienced in taking a customer’s requirements and turning them into specifications. The very latest design tools are employed by leaders in their own fields, such as Cadence, Ansys, and Allegro, including modeling and simulation tools and PCB design environments. With a focus on electromechanical applications, Napino’s engineers also use the most advanced software tools for electric motor design.

As all electronic products today are mostly defined through software, the engineering team also follows internationally recognized development practices, such as complying with MISRA C coding standards for developing safety-critical embedded software. Napino engineers also make use of hardware-in-the-loop development flows. As the design evolves, Napino’s engineers employ advanced simulation tools for electromechanical design and thermal analysis, to ensure the highest levels of reliability.

Prototype testing is another critical stage and the facilities here include highly accelerated stress testing, environmental chambers, vibration testing, and even a salt spray chamber. No aspect of the product’s design is left untested before it is presented to the customer.

When it comes to a rapid expansion of your design team, there is no easy route. However, by working with Napino Digital Solutions, you can gain access to a world-class team of engineers experienced in using the industry’s very best tools and meeting the most stringent standards.